Waste equals food in John Edel’s vernacular. When it comes to running a business, the Chicago entrepreneur prefers to think in terms of complex food/waste chains much like those found in nature, which celebrate the relativity of refuse and resource. Edel is the founder of “The Plant,” an old meatpacking facility transformed into a social enterprise that will grow food sustainably while producing zero net waste.

Currently, one-third of the building consists of aquaponic vertical farm space while two-thirds will house bakeries, breweries, a commerical kitchen, and Tilapia fish hatcheries. Five tenants, including the aquaponics businesses 312 Aquaponics and Greens and Gills, already operate.

Earlier this week the Plant welcomed hundreds of visitors at its spring open house, a bi-yearly opportunity to get free tours, taste Kombucha tea and other organic goodies, peruse the rooftop gardens, and learn more about sustainable urban living.

It had much to celebrate: subsidized by a recent $1.5 million grant from Illinois Department of Commerce and Economic Opportunity, The Plant expects much growth in the coming months. Techli caught up with TP to ask the burning question: how do the pieces of this energy puzzle fit to provide zero net waste?

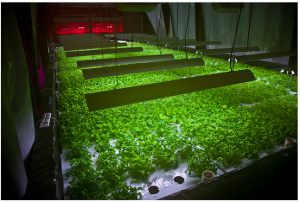

Aquaponic farm

Aquaponic technology combines aquaculture (the Tilapia fish farm) and hydroponics (soil-free plant growth). The nitrates and ammonia from the fish fertilize the plants, while plant-filtered water houses the fish, forming a closed loop where waste equals food.

LED technology provides the radiation necessary to trigger photosynthesis in the leafy greens, with the future goal of pinpointing specific frequencies catered to individual plant specie needs.

Anaerobic digestor

Meanwhile, the fish, food, and brewery waste feeds an anaerobic digestor, a bacterial incubator that breaks down these contents via anerobic respiration and outputs fertilizer and algae to feed the plants and fish, respectively. The digestor is central to the Plant’s success, converting the organic waste into reusable fertilizer/fish food.

Brewery

Commercial development for a brewery is also underway, with the spent grain providing additional waste/food for the anerobic digestor. The spent barley will also feed the fish and sustain the mushroom farm downstairs.

A separate Kombucha tea brewery, Arize Kombucha, already a tenant, feeds the plants its CO2 output while the plants’ oxygen output ferments the tea.This forms another closed food/waste loop.

Turbine generator

A turbine generator to be built by Eisenmann fulfills the facility’s electrical needs, with the resultant CO2 feeding the plants. Powered by the anerobic digestor’s bio gas, this last piece of the energy puzzle will complete the zero net waste loop.

Set to be fully operational by 2017, The Plant will generate 125 jobs for Chicago’s economically troubled Back of the Yards neighborhood while remaining off the grid, a definite push for the city’s sustainable future.