I remember the day vividly. It was the summer of 2012 and I was about to enter my freshman year of college. Instead of spending my days playing video games, watching Netflix, or relaxing by the pool, I was working 2 jobs – a full time internship and a part time sales job at Best Buy Mobile. One day, another intern at the office, Taylor, was working on something that happened to catch my eye, a 2 layered iPhone case that was different than any of the other cases I had seen at Best Buy. I figured he was on to something, so I naively asked him, “do you want to go into business together?” Little did I know that him saying “yes” would change my life forever.

It felt like a scene straight out of the movie “Step Brothers.” We had an awesome idea, a great team, and the motivation to make it happen. We were high on life, and together we formed our company, Dual Cases. But that buzz quickly began to fade when reality set back in. Between the two of us, we had never brought a product to market before, Taylor and I were still in school, and even the idea of trying to begin manufacturing our case made our knees shake.

Most people never start a company, yet alone try to make a physical product. The daunting nature of this can cause most people to give up on their ideas before they even start. I’m here to tell you that creating a product and bringing it to market is not only achievable, it’s extremely rewarding. Now, let me tell you how.

Prototyping

Entrepreneurship isn’t some secret club that you need an invitation to join. But you aren’t an entrepreneur until you stop talking about doing it, and you just simply do it. At this point, most people ask “how?” I respond, “Do you own a hot glue gun? Do you have some cardboard lying around? You can start now.” Prototyping is a very crude process. It usually doesn’t involve a bunch of men in white coats in a lab mixing chemicals and nodding their heads. The purpose of prototyping is to create something that other people can touch and feel while giving them a glimpse into the possibilities of what you could eventually create. Don’t spend thousands of dollars developing a prototype. Trust me. Instead, make a very rough version of your product. I’ll explain why a bit later

If you are lucky enough to have someone who is good with Computer Aided Design (CAD) on your team, then developing a digital model of your product can be incredibly valuable. Fortunately, the internship Taylor and I met as was at a reseller for CAD software, so we were both familiar with the different software options and how to use them. Some of these software programs, such as Autodesk Inventor, Siemens SolidEdge, and Solidworks, offer free trials or discount programs. Autodesk Inventor even offers a free download of their Inventor Professional program with a valid student email address, which is good for 3 years.

If you don’t have someone with that skillset at your disposal, then you have two options – learn how to do it yourself or hire someone to do it for you. Most of the basic functionality of CAD can be learned through free content online, such as how-to guides or video tutorials. There are even some public libraries that offer free instructional courses and access to CAD programs. If you have a bit of money that you are willing to invest in your idea, hiring somebody to make a 3D model for you can be expensive, but much faster and more reliable than doing it yourself.

Once you have a 3D model of your product, you can utilize a process called 3D printing. 3D printing an object can be done using different processes such as FDM, SLS, SLA, but unless you need a prototype that has high strength or high detail, then using a website such as sculpteo.com or shapeways.com should allow you to get a great looking prototype in your choice of color and material. These sites allow you to upload your CAD file and will then 3D print and ship you your product. We made over a dozen 3D printed prototypes, all for around $25 a piece.

Validation

Use these prototypes to get feedback from friends, family, and random strangers. Especially random strangers. Use their feedback to continuously make improvements. As I said before, don’t spend a ton of money on a single prototype. Instead, try and create a prototype without any bells and whistles. This is often referred to as a Minimum Viable Product, or MVP. Now, get feedback and make improvements. And each time you get feedback, ask the person if they would pay you for this product. Saying “that’s a good idea” doesn’t cost anything, but if you ask them for money, you’ll be able to get a much better sense of whether your product will do well in the marketplace. Continue to make improvements and refine your product until people not only say they would pay for it, but ask you when they can get one.

Once you start getting this response, you can do a couple of different things. For one, if your product is novel enough, you may want to talk to a patent lawyer. Most will provide you with a free consultation, and then you can decide if it’s worth it to spend thousands of dollars on a patent.

Next you’ll want to begin lining up a manufacturer. Determining whether to manufacture in the US vs. overseas has been debated for a while. All I can say is that we weren’t able to afford manufacturing in the US, so we resorted to manufacturing in China.

After you find a manufacturer that you trust, its time to validate your idea in the marketplace. The traditional way to do this is by paying for a bunch of inventory, with sales coming second. You could bootstrap it and try to raise money from friends and family. Or, if you’re really lucky, you might get an angel investor or venture capitalist that understands your vision to invest in the company. For Dual Cases, we were fortunate enough to bring an angel investor onboard this past summer, allowing us to begin manufacturing.

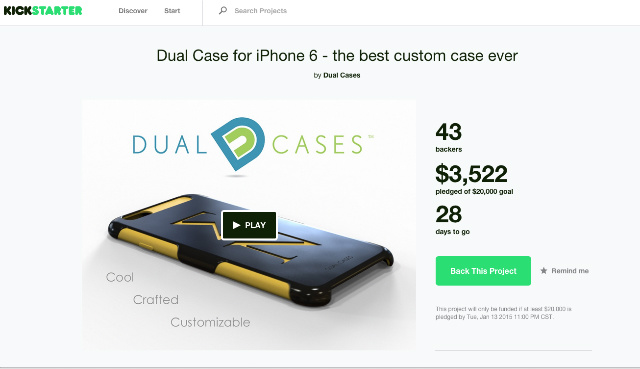

However, a new method of raising funds is through a crowdfunding platform such as Kickstarter. Putting your project on Kickstarter has many benefits outside of just raising the money to bring your product to market. Sure, if you’re successful, the money can be great, but it also serves as an ideal platform for validation. Hitting or exceeding your funding goal demonstrates that people are willing to put their money where their mouth is. Keep in mind that this validation is done before ever paying for manufacturing or inventory, which is a huge plus.

We decided that the benefits of Kickstarter were worth the effort, so just this past week we launched a Kickstarter for the Dual Case for iPhone 6. We were fortunate enough to raise over $3,000 within the first 72 hours, but with a funding goal of $20,000, we are continuing to try and spread the word.

You can view our campaign, follow our progress, or become a backer here: ?kck.st/1qvccJi

Summary

I have people approach me all the time with new product ideas. I ask them what’s stopping them from executing on their idea, and they’re always more than happy to provide excuses. Everybody can come up with an excuse for why they can’t do it. I was a student. I had two jobs. I had no connections and no experience doing anything like this before. But I kept pushing and I was patient. It took us two years to find an investor and perfect our design. These things don’t have to happen right away. Baby steps are just as effective. Make a prototype, get feedback, and continue to improve. Seeing your idea progress will be one of the most rewarding things you’ve ever done. Who knows? Maybe one day your product will be on the shelves of retail. So what do you have to lose?